XPRIMER.CMMS – much more than just support for the maintenance department

XPRIMER.CMMS (Computerised Maintenance Management Systems) is a specialised tool designed to ensure the reliability and availability of a company’s resources in order to achieve appropriate productivity. It supports the work of technical departments by digitalising maintenance processes and enables an efficient exchange of integrated information.

By digitalising your maintenance processes in XPRIMER.CMMS, you ensure increased productivity of your company.

XPRIMER.CMMS can be used as an independent system and, at the same time, the versatility of its configuration and the possibility of integration with other production management systems enables to achieve the synergy effect in the process of production control. With the seamless exchange of information between systems, the users experience better efficiency of their actions.

Ensure greater availability of production resources with XPRIMER.CMMS

Save time for your team

thanks to a mobile application that provides constant access to online information regarding incidents and actions taken.

Boost machines' reliability

by creating overhaul, inspection and maintenance plans as well as taking appropriate preventive actions.

Reduce costs

by efficiently managing the available machines, spare parts warehouse and automating the stock replenishment processes.

Improve communication

by using a mobile app to properly manage your maintenance personnel.

Set new standards

by digitalising the process of knowledge management, documentation, repair manuals and service procedures.

Increase work safety

by ensuring the proper operation of machines, in compliance with regulations and guidelines of machine and equipment manufacturers.

See how XPRIMER.CMMS works in practice

Contact us and arrange a meeting, during which we will present how XPRIMER.CMMS works.

Explore the functionalities of XPRIMER.CMMS

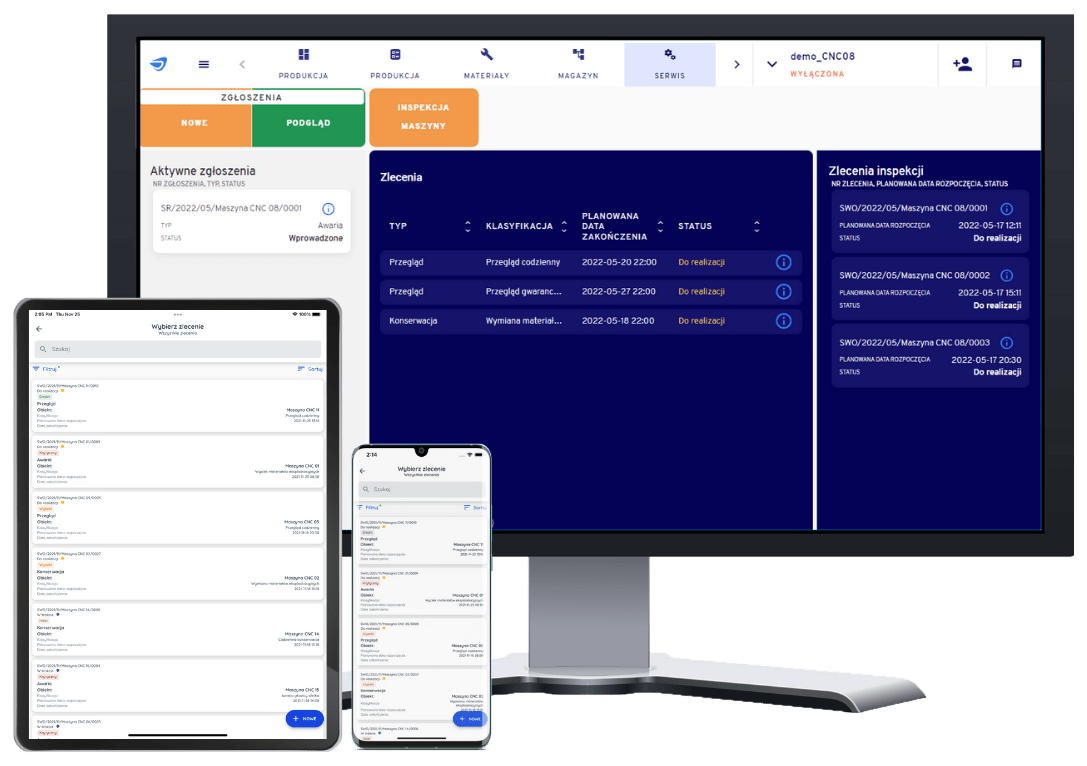

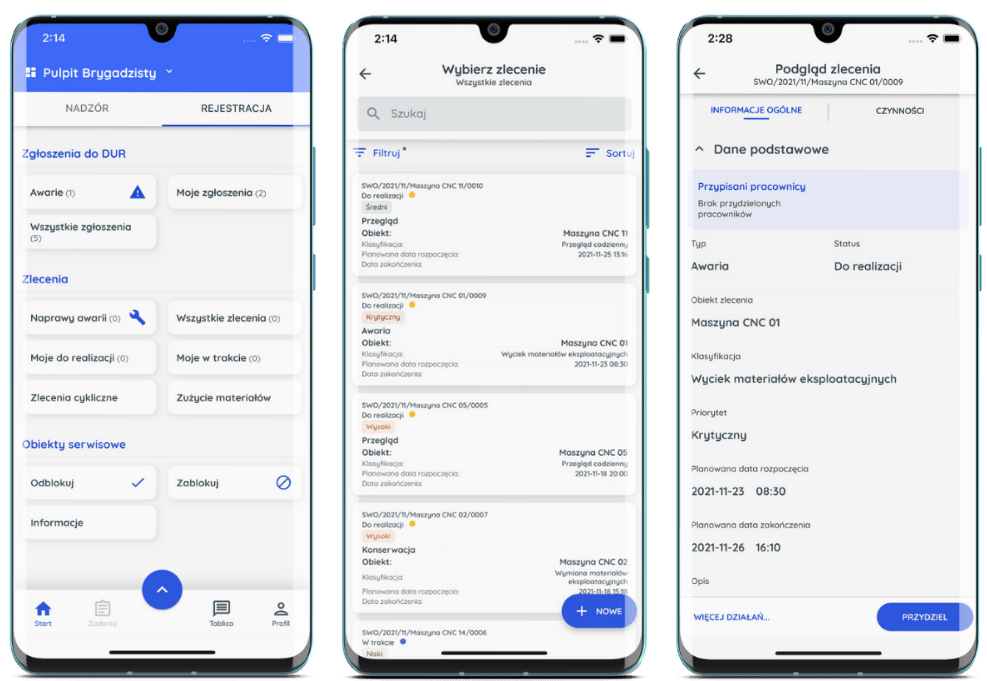

Provide full access to key information anytime, anywhere

Thanks to the mobile application included in XPRIMER.CMMS, maintenance departments have the opportunity to immediately respond to incidents related to failures or defects.

Use a smartphone or tablet to manage service requests, cyclical orders, delegate tasks to your personnel and verify their completion status. Users of the mobile app receive notifications via SMS, email or push messages. They see a list of service requests on their mobile device dashboard with assigned priority and status.

XPRIMER.CMMS also gives you the ability to keep working hours records for maintenance personnel.

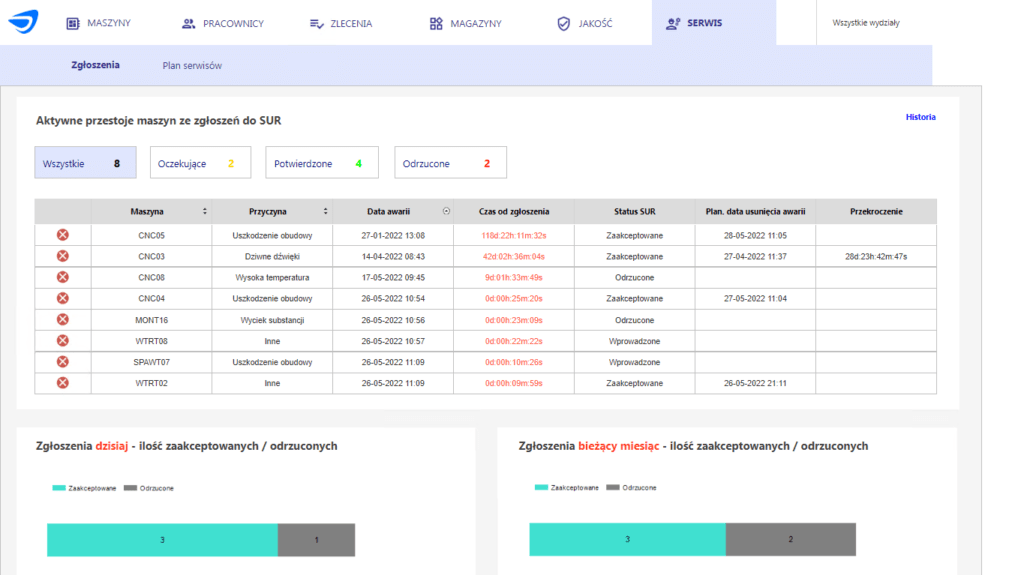

Monitor key metrics related to production resource availability

XPRIMER.CMMS provides key information from the point of view of production management and modification of production plans: the date of resolving the failure, i.e. the date when the resource will be available for use again.

Based on the recorded data, the XPRIMER.CMMS calculates MRT (mean response time), MTTR (mean time to repair a failure), MTTF (mean time to failure) and MTBF (mean time between failures).

Get full synchronisation between the activities of maintenance and production departments

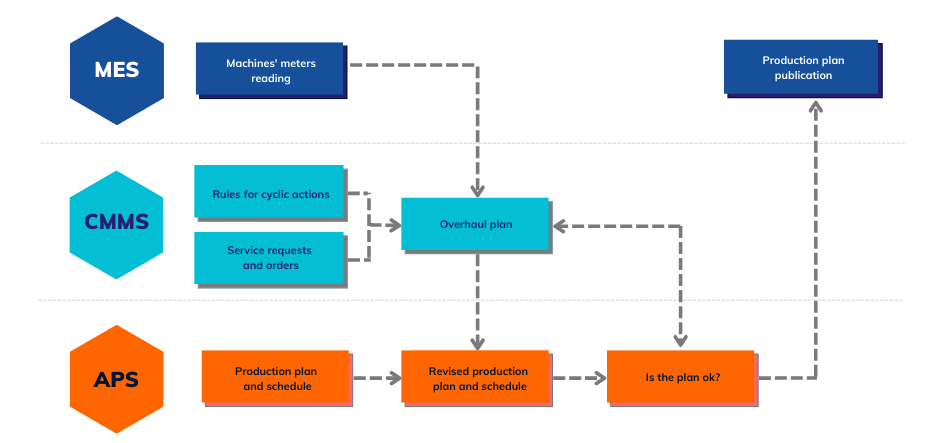

XPRIMER.CMMS provides full information exchange between the maintenance department and the production planning department. Full synchronisation of activities allows to create overhaul plans, taking into account the priorities of production plans. At the same time, production planners can include overhaul plans in their schedules.

XPRIMER.CMMS shows resource availability dates. These dates are included in production plans and in the publication of these plans by the MES. The flow of information between CMMS, APS and MES allows for quick modification of production plans in case of unplanned downtime.

Support autonomous operations as part of Total Productive Maintenance

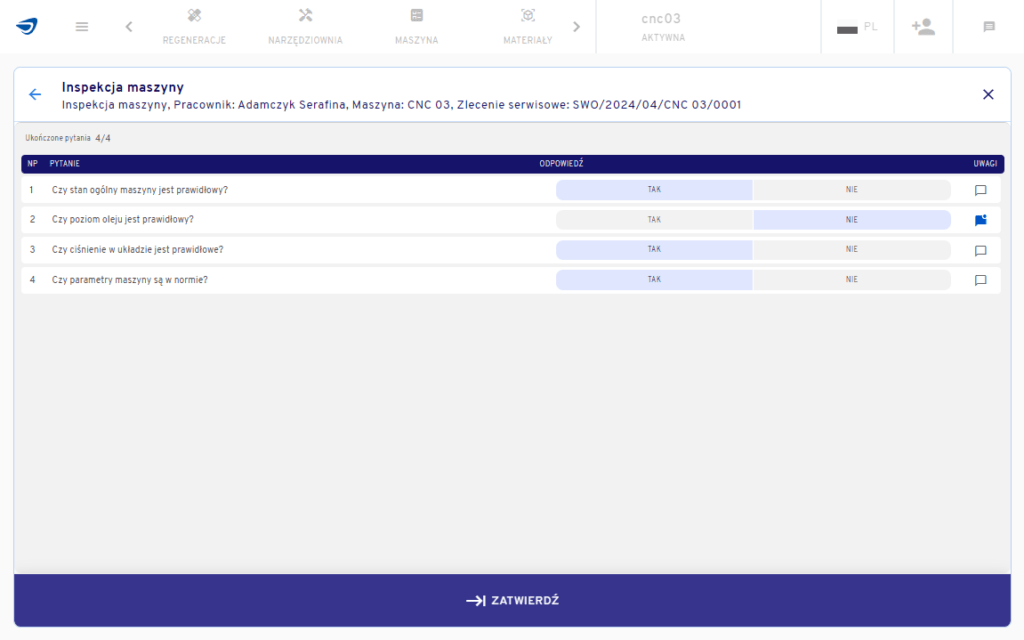

XPRIMER.CMMS allows to increase the independence of production employees. They have the possibility to record the inspection activities performed on the machine using the production terminal. It is possible to implement inspection procedures before starting the machine or after concluding operations.

In addition, the operators can report machine failures from the production terminal and carry out simple repairs which do not require the intervention of the maintenance department on their own. This relieves maintenance personnel from performing tasks that do not require a high level of expertise. Increasing the autonomy of production employees is the basis for building Autonomous Maintenance.

Streamline the flow of information between your CMMS and ERP system

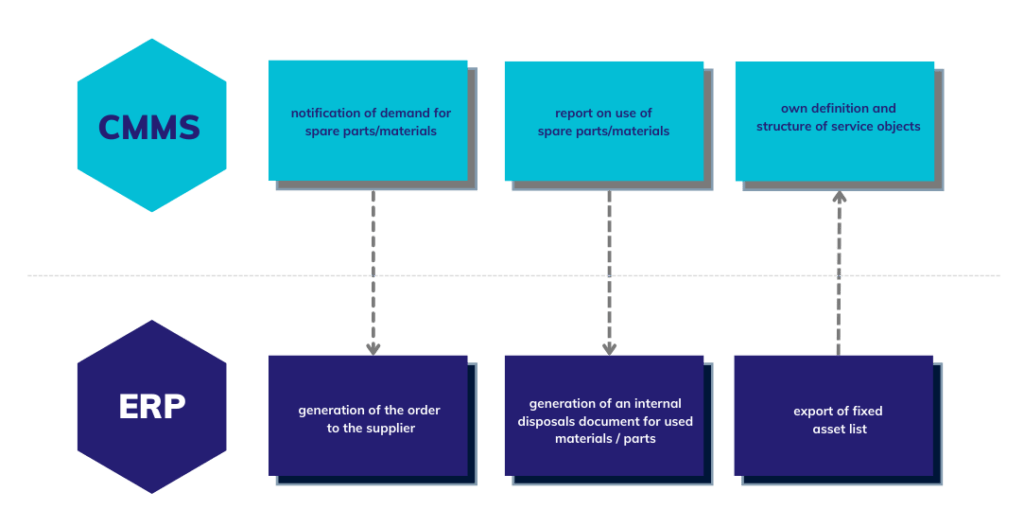

Based on standard mechanisms available in XPRIMER, it is possible to automatically report demand for parts and generate an internal issue document for consumed materials/parts in the ERP system.

It is also possible to export the list of fixed assets from the fixed assets module in the ERP system and then, on this basis, independently define and create a tree structure of machines and equipment suitable for specific maintenance services in XPRIMER.CMMS. This structure can be constructed freely, regardless of the definitions in ERP or physical locations of machines.

See how XPRIMER.CMMS works in practice

Contact us and arrange a meeting, during which we will present how XPRIMER.CMMS works.

Explore XPRIMER users reviews