Integrated production management

MOM (Manufacturing Operations Management) is a manufacturing process management solution with a focus on informed decision-making, effective planning, efficient operations and quality management for better productivity of the company.

XPRIMER in the area of MOM provides full control over the flow of information – from order to execution. It plans and schedules production and supervises its progress, providing data to evaluate its efficiency. It enables extending the functionality and increasing the flexibility of operations by adding new, relevant industrial applications, as individual areas of your company improve and new business objectives are set.

XPRIMER brings to your company a combination of the knowledge of our experts and the experience of our clients

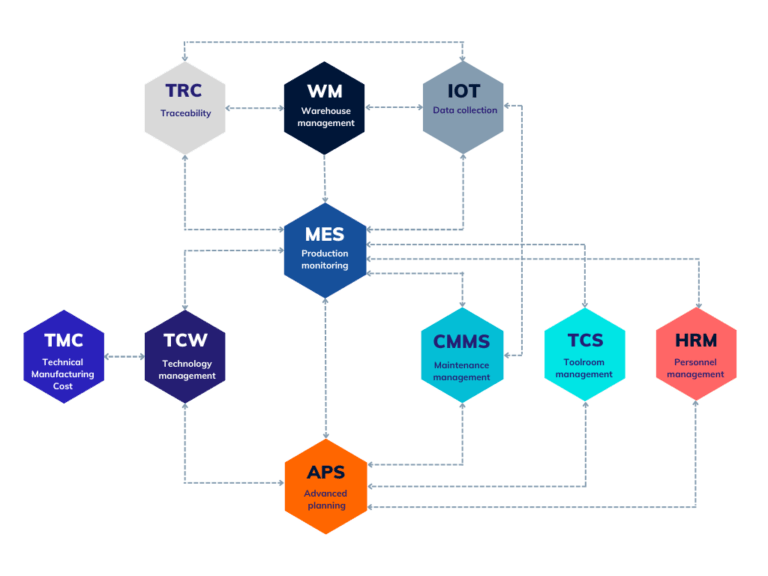

Explore the different areas of MOM supported by the eq system

Choose holistic production management

Gain operational flexibility

- Anticipate and prevent problems and bottlenecks

- Make realistic and feasible plans

- Reduce lead times

- Project production capacity

Improve plant productivity

- Increase the availability of machines

- Better synchronise processes and resources

- Monitor micro-downtime

- Control OEE

Reduce production costs

- Reduce inventory and work in progress

- Automate repetitive processes

- Use available resources more efficiently

- Design technical manufacturing cost

Increase work efficiency

- Improve internal communication

- Manage staff, their availability and competences more efficiently

- Ensure transparency in the performance of tasks

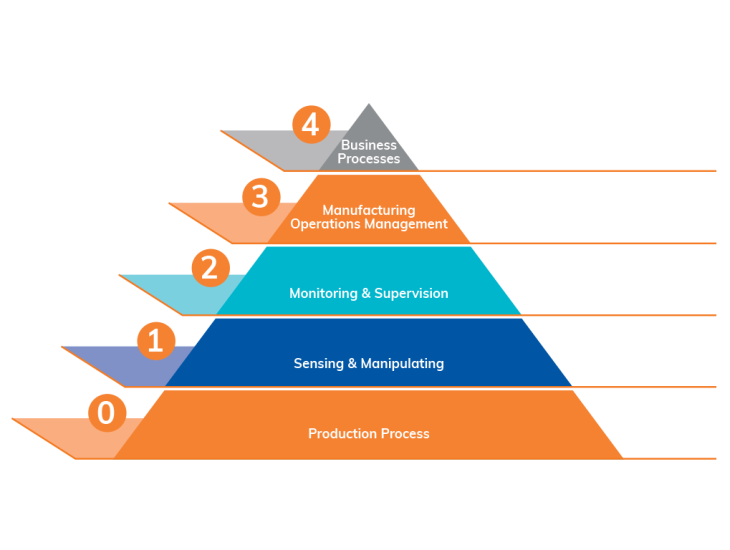

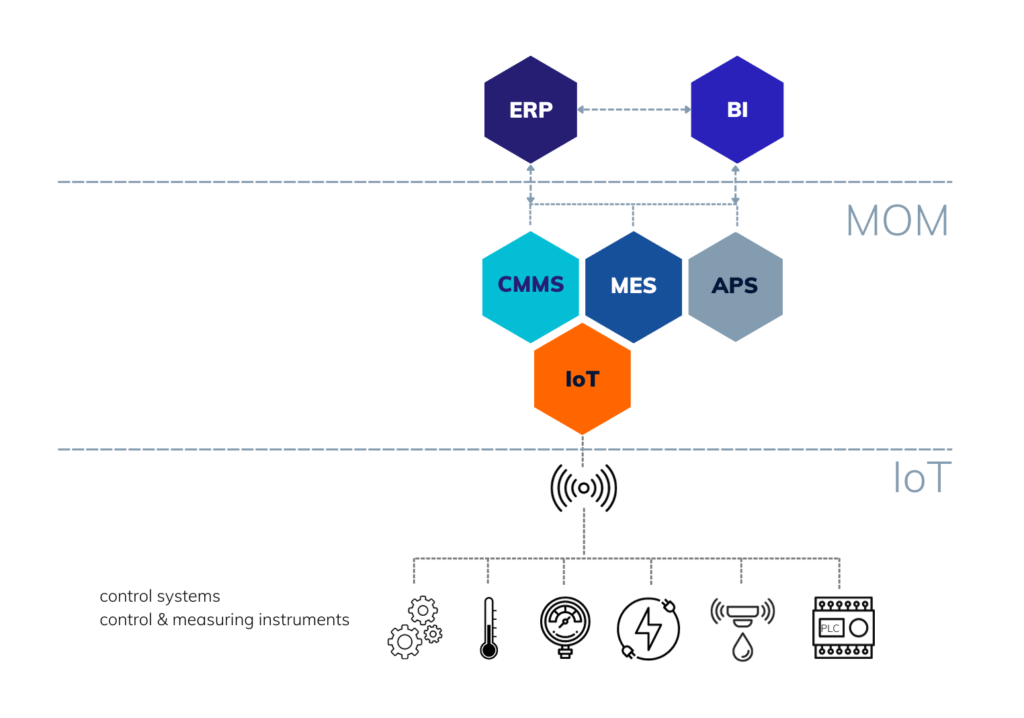

According to the ISA 95 standard developed by the International Society of Automation, the MOM system is ranked as the third layer in the management of a manufacturing company.

Discover the core functionalities of XPRIMER in the area of Manufacturing Operations Management

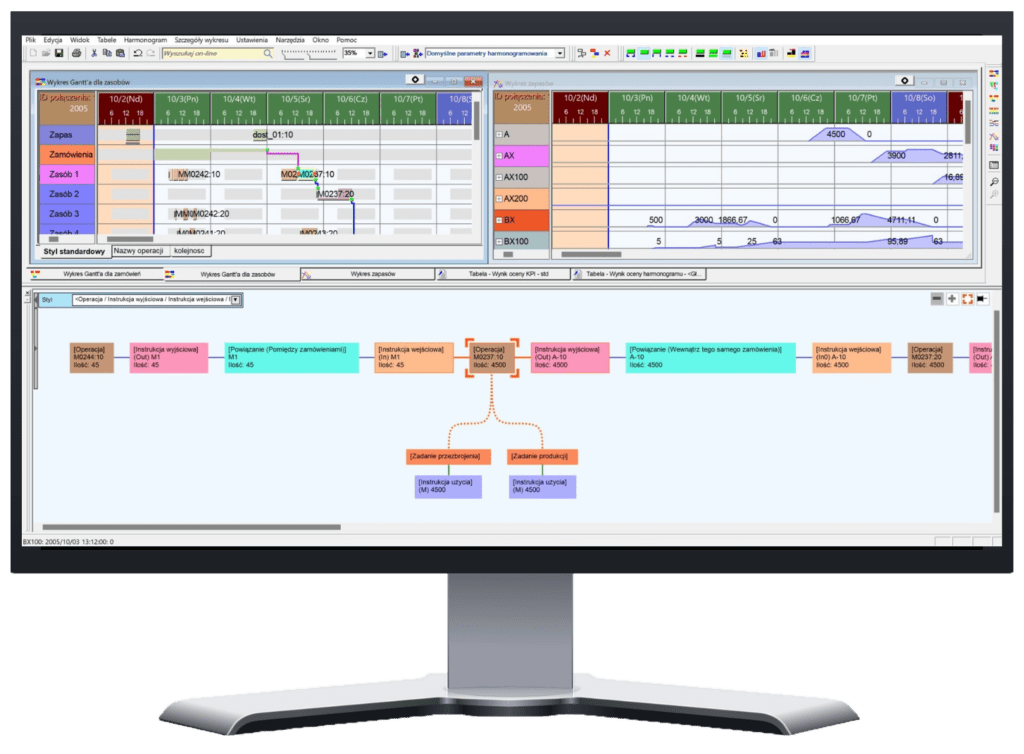

Solving production planning and scheduling problems

ASPROVA APS (Advanced Planning and Scheduling) is a specialised system designed to improve production management processes, particularly in areas of production planning and scheduling.

As the world’s fastest production scheduling system, ASPROVA APS creates a plan at the click of a button, taking into account full production logistics and ensuring efficient material and information flow.

ASPROVA APS is a solution that, with its flexibility and extensive development possibilities, gives you the confidence that will meet both current expectations and those that will arise in the future.

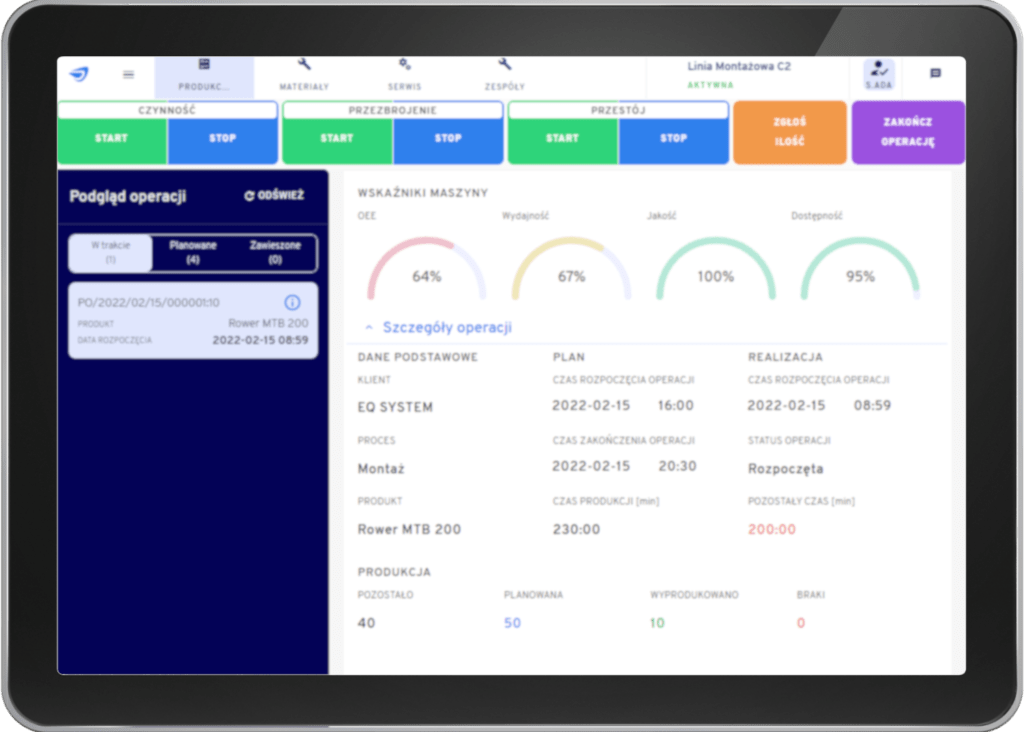

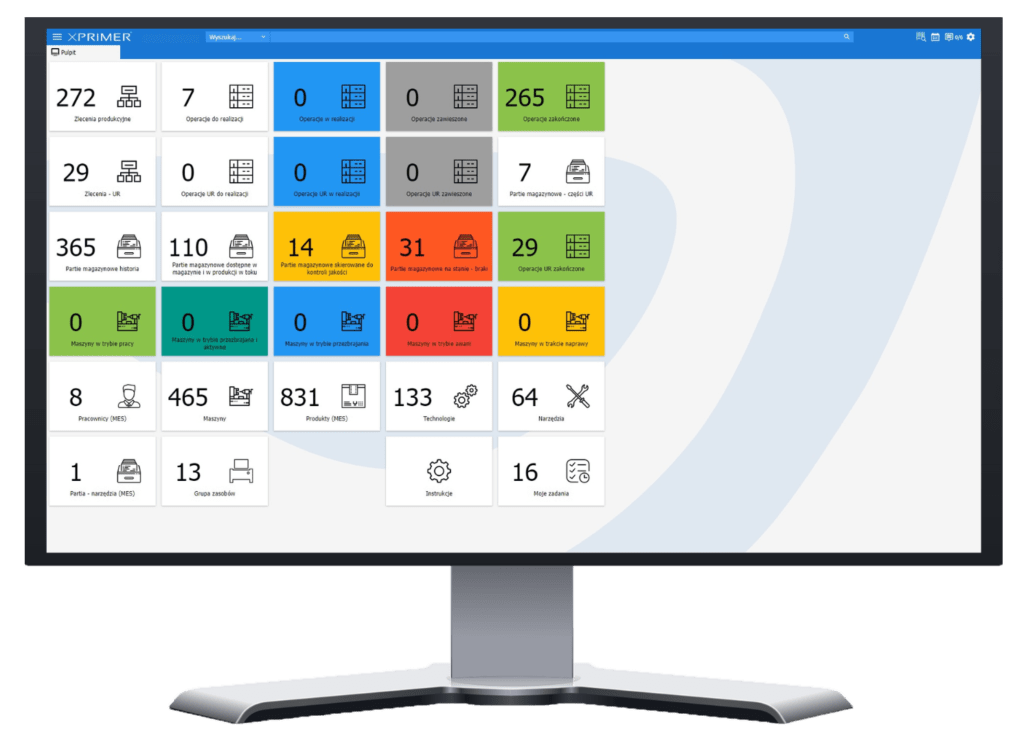

Key data on your production process available online

XPRIMER.MES (Manufacturing Execution System) is a reliable solution for mapping real production events, providing accurate information to help you to make the right decisions.

XPRIMER.MES has proven its effectiveness in many industries and diverse production processes. Developed in close cooperation with manufacturing companies, it provides data that is used in, among other areas, production planning, technology management, cost accounting, material picking or production maintenance.

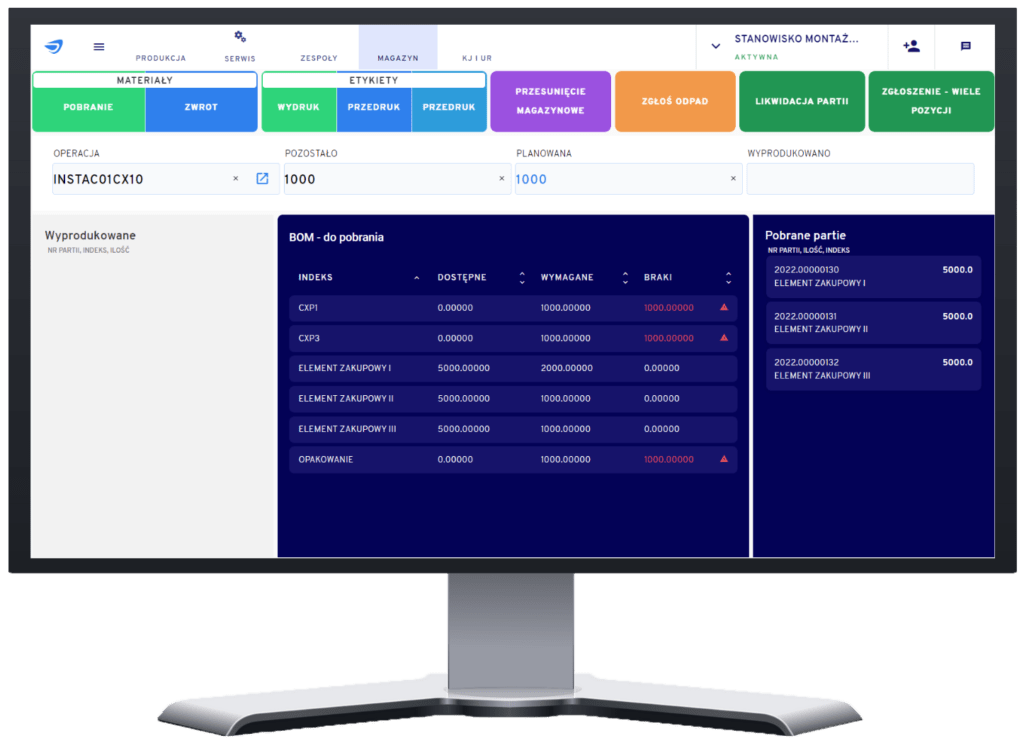

Digital control of the product in compliance with traceability requirements

XPRIMER.TRC (traceability) enables the recording of the relationships between manufactured and consumed materials in the production process.

It also allows necessary parameters to be tracked, such as production date and time, part serial number, operator ID, job identification, operation number, production plant number, recording of process parameters (as required for individual operations), identification of process sequence and BOM recording.

Smart manufacturing within Industry 4.0

XPRIMER.IoT (Internet of Things) is a set of tools for information exchange in a production facility between sensors, devices, machines, controllers, databases and other IT systems, in particular the MES system.

The data provided via XPRIMER.IoT increases the degree of precision and reliability of the information available in XPRIMER.MES, which is the basis for improving production control processes and optimising the use of existing production resources.

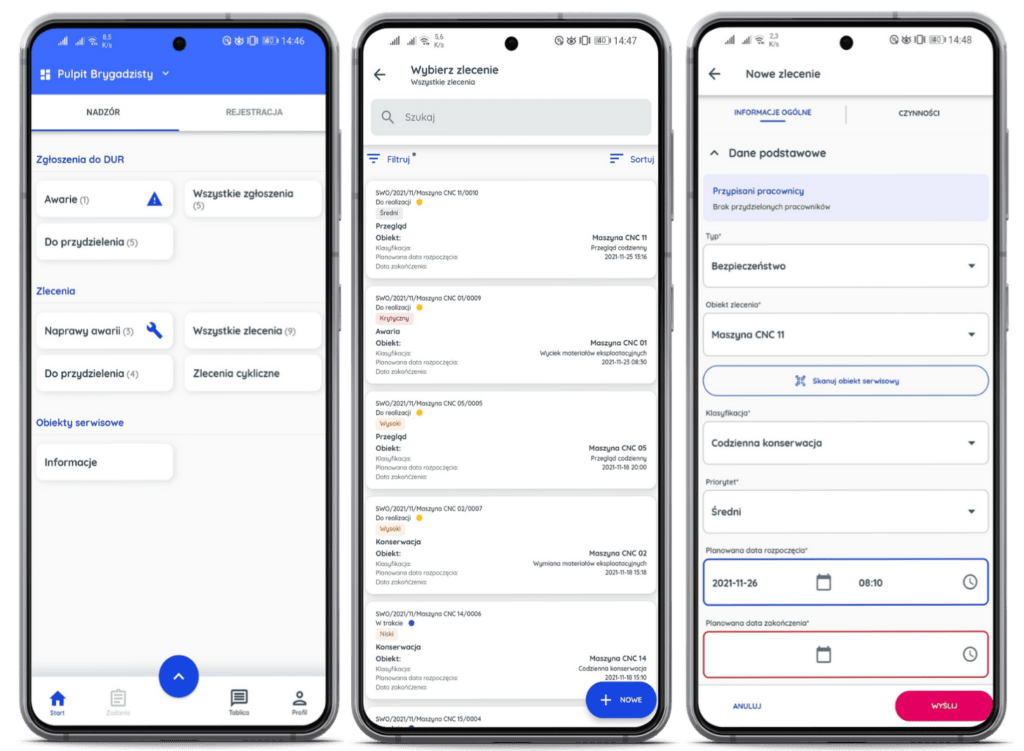

Greater availability of production resources thanks to Total Production Maintenance

XPRIMER.CMMS (Computerised Maintenance Management Systems) is a specialised tool designed to ensure the reliability and availability of a company’s resources for adequate productivity. It supports the work of technical departments by digitalising maintenance processes and enabling the efficient exchange of integrated information.

By digitalising maintenance processes in XPRIMER.CMMS, you ensure that your company’s productivity increases.

A comprehensive repository of technological data available online

XPRIMER.TCW (Technology Creator Wizard) is a specialised tool that gives you complete freedom in technology management – you decide which elements to use to build them.

Technology management in XPRIMER.TCW enables not only the actual production process to be reflected, but also all the constraints that should be taken into account in the planning and scheduling process. This makes XPRIMER.TCW the ideal tool to complement the ASPROVA APS production planning system.

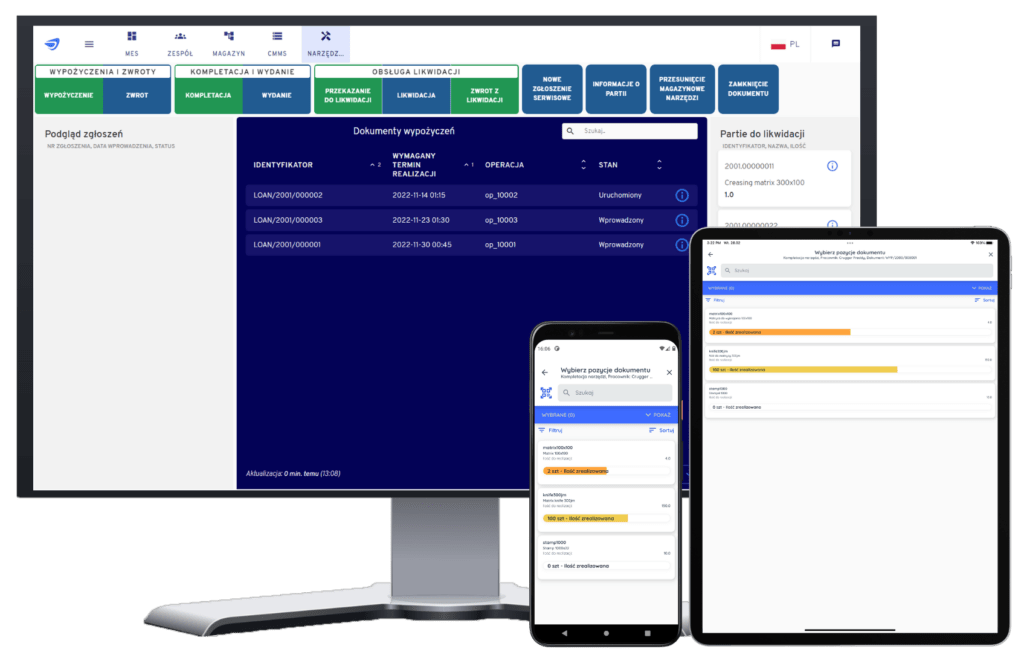

Improvement of work organisation and resource efficiency

XPRIMER.TCS (Tool Control System) is an easy-to-use system for managing tools and instrumentation used in the production process.

XPRIMER.TCS, accessible from a browser and mobile app, enables quick and efficient handing over and reception of tools, control of their location and verification of their consumption rate based on data from the XPRIMER.MES system, as well as management of their reconditioning, calibration/legalisation or disposal.

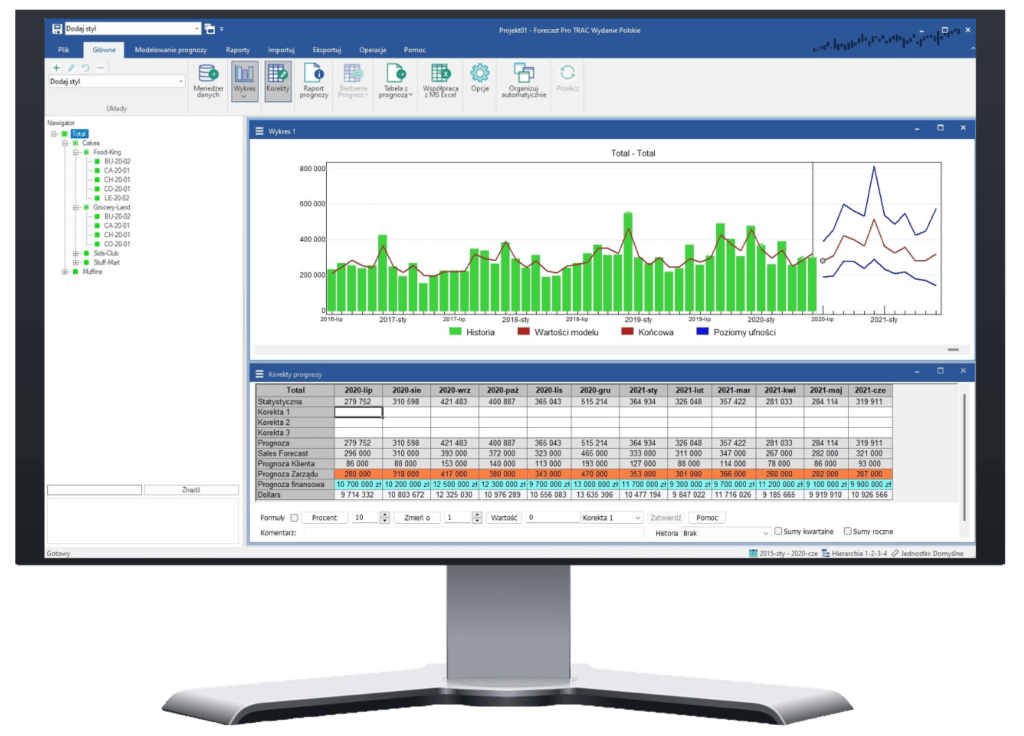

Reliable forecasts leading to better decisions

Forecast PRO is a well-proven tool used by organisations around the world to create accurate forecasts (demand, sales, resource requirements, employees or new products) that can be easily integrated into planning systems (including ASPROVA APS for production planning or XPRIMER.HRM for work schedule planning).

The tool for effective management, monitoring and improvement of forecasting processes creates reliable business forecasts for you within seconds.

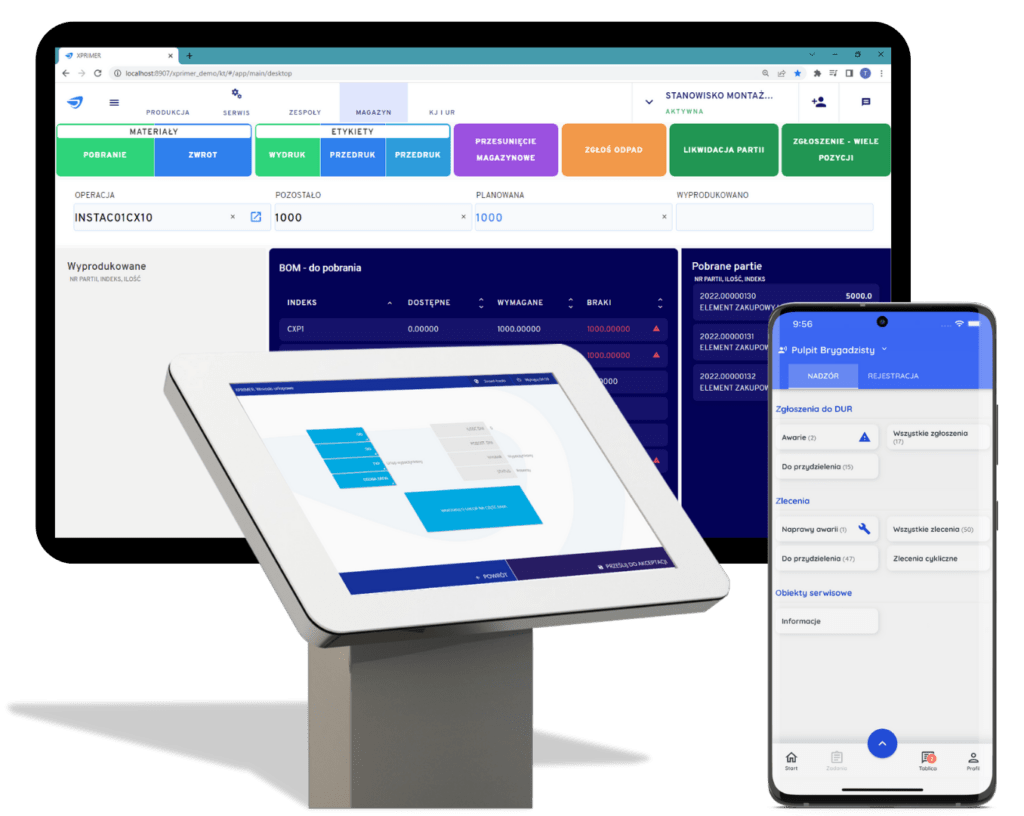

Waste elimination in manufacturing thanks to the mobile app

The XPRIMER mobile app for production management is a tool that increases employee mobility in production recording and reporting, maintenance work, toolroom management and employee self-service in HR matters.

In addition to desktop computers, employee kiosks and production terminals, the mobile application as part of the XPRIMER platform is another way of data access that improves business management.

Regardless of your position in the organisation, your function or the tasks you perform, with the XPRIMER mobile app you will streamline your work and that of your team.

Information flow across different modules in the MOM area

See how XPRIMER in the MOM area can optimize processes in your company

Explore customer feedback on the MOM solutions offered by eq system