XPRIMER.MES - key production data available online

XPRIMER.MES (Manufacturing Execution System) is a reliable solution for mapping real manufacturing incidents, providing reliable information, assisting in making correct decisions.

Combining the digital world with the physical world of manufacturing, XPRIMER.MES provides holistic production management for the modern enterprise.

XPRIMER.MES has proven its effectiveness in many industries and diverse manufacturing processes. In response to the needs of our customers, we are constantly developing the list of functionalities.

Optimise your processes using the information provided by XPRIMER.MES

Reduce production costs

by using material accounting records and information on machine load levels

and staff efficiency.

Improve production quality

by continuously monitoring the tasks performed and analysing data regarding production rejects

and their causes.

Reduce production process time

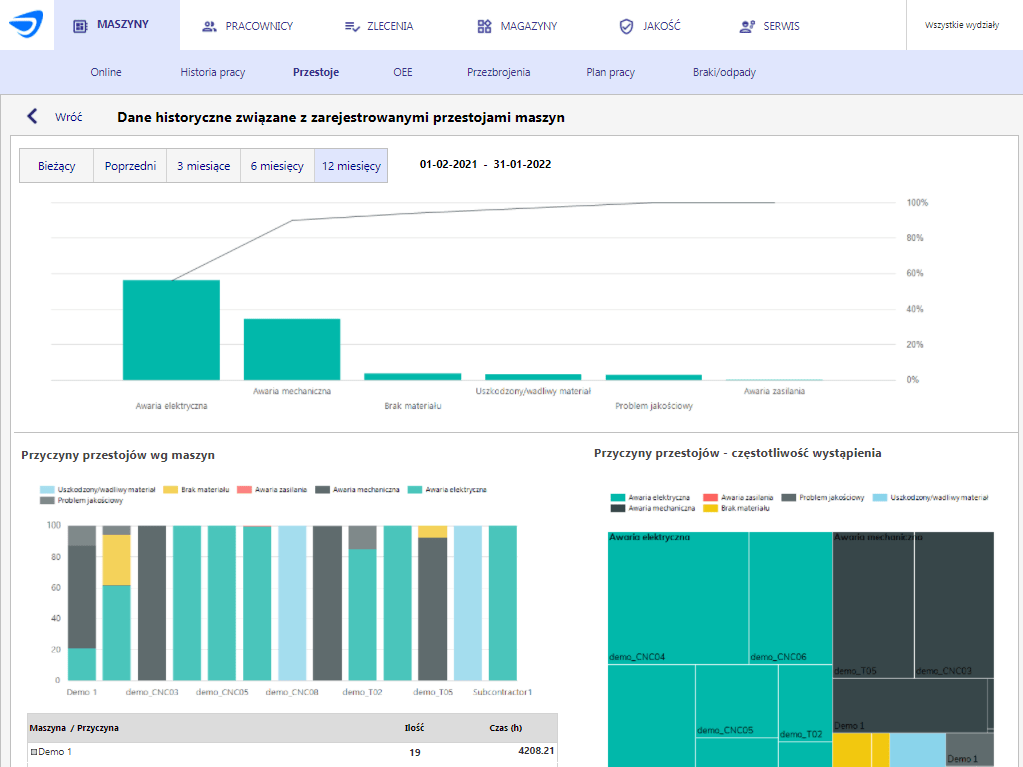

through the registration of downtime recorded in the MES system, analysing it, and taking into account the necessary changes in production planning.

Increase work discipline

by recording the activities performed by employees in the MES system.

Reduce equipment failure

by analysing information about micro downtimes and failures provided by the MES system.

Reduce waste

by using the detailed information about process disruptions and downtimes,

production rejects and waste registered in the MES system.

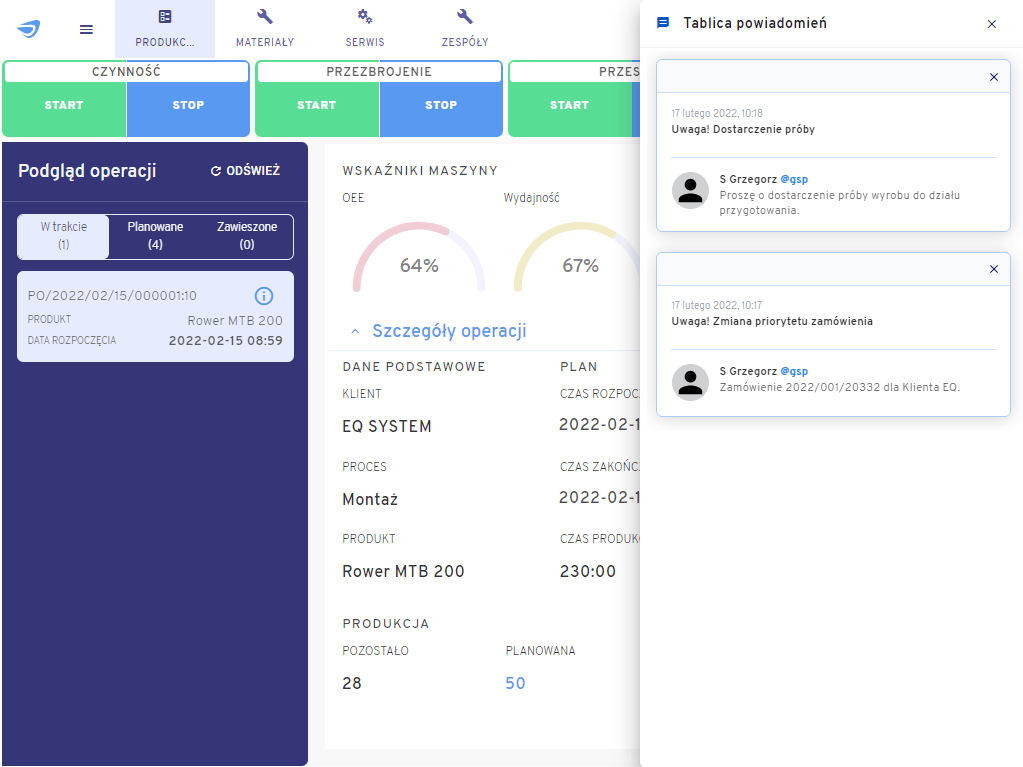

Make quick decisions

thanks to reports based on reliable data

from the MES system and other systems used in production (APS, CMMS, ERP).

Ensure continuous improvement

by monitoring the status of order performance

and the level of key indicators, calculated in real time.

Increase sales value

by engaging previously unused capacity identified by the MES system.

See what benefits our customers have gained by implementing XPRIMER.MES

Read stories of customers who have streamlined their manufacturing processes with us.

Explore the functionalities of XPRIMER.MES

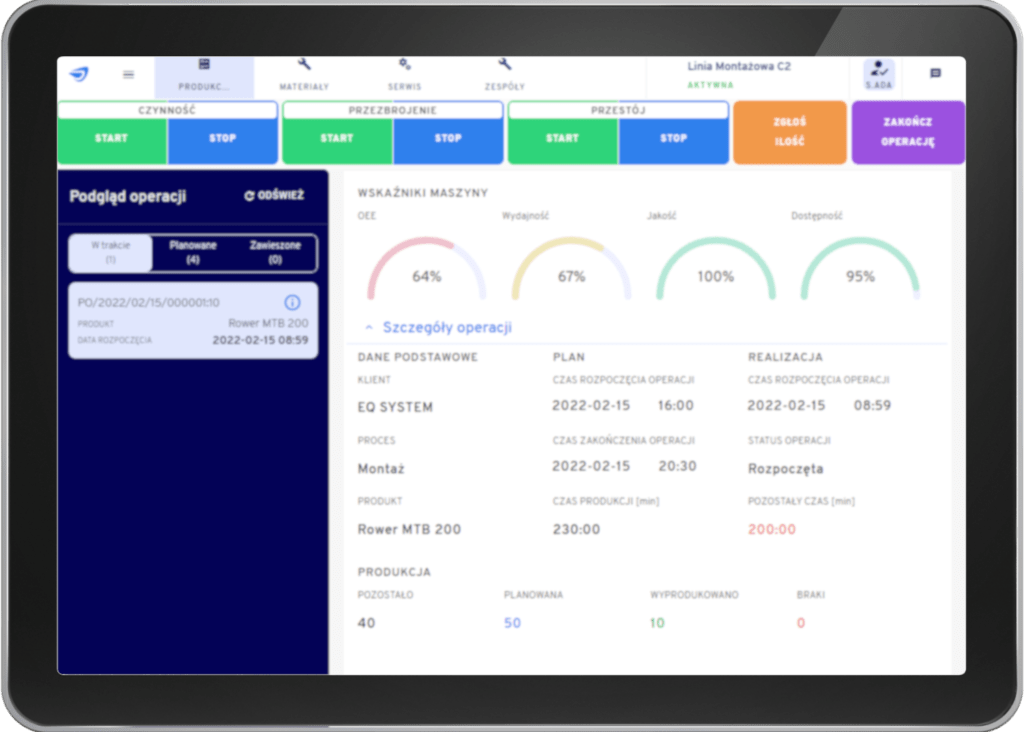

Comprehensively manage production performance

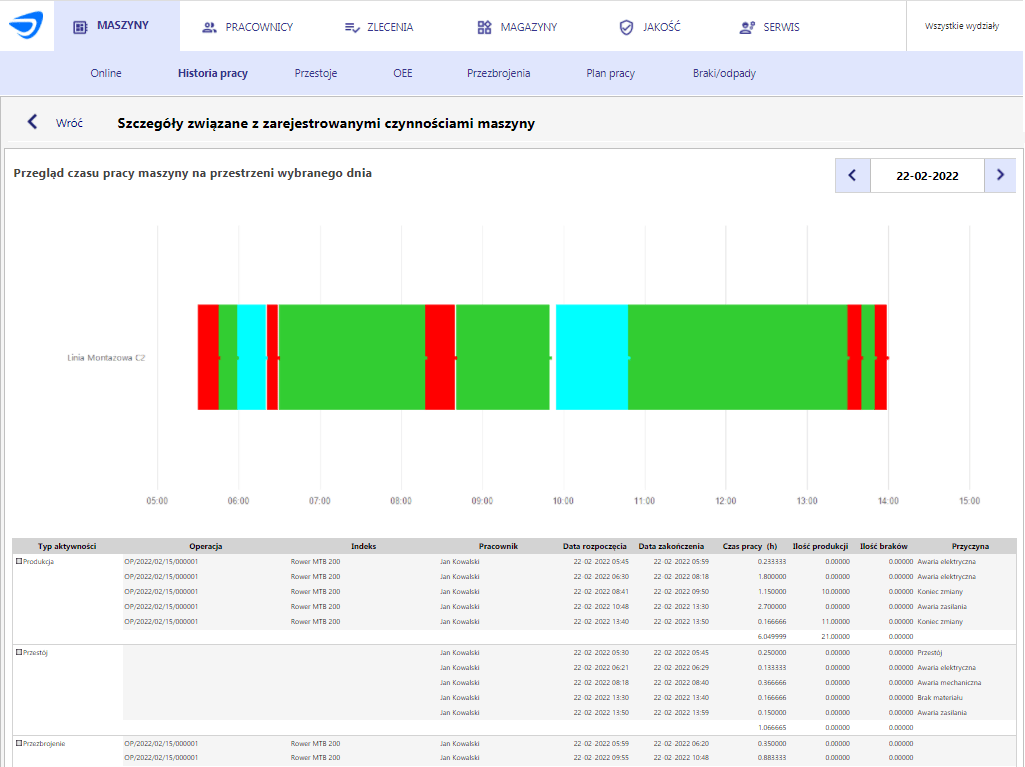

XPRIMER.MES collects all data regarding the performance of production processes, the status and working time of production resources and the progress of production orders with the accuracy of a single operation.

XPPRIMER.MES can be used as an independent system. At the same time, the system architecture enables integration into the entire production control cycle. Data obtained from XPRIMER.MES can be used in production planning, technology management, cost accounting, material picking, equipment maintenance and more.

This makes XPRIMER.MES one of the components of a comprehensive production management system.

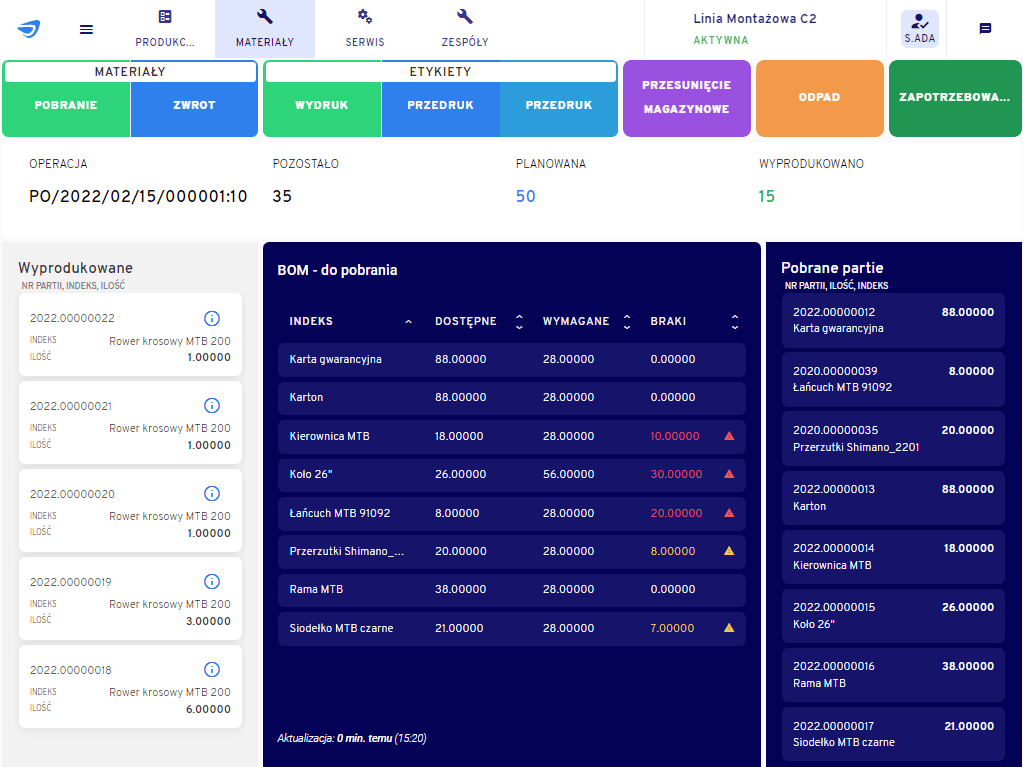

Increase the level of trust in your products using traceability

XPRIMER.MES is the perfect tool to create process genealogy and product structure according to traceability, with the accuracy of single batch or even individual unit.

XPRIMER.MES makes it possible to track batches, material flow, as well as to monitor changes in recipes made by personnel and parameters of the production process in the context of a given production batch. It also provides access to information about the current stock inventory for the production in progress.

Provide online access to status information regarding manufacturing resources

XPRIMER.MES provides information about the status of machines, orders, employee activity and materials needed for a given operation. This information is available in real time in the browser.

Based on reliable data available online, decisions can be made that affect better use of free resources.

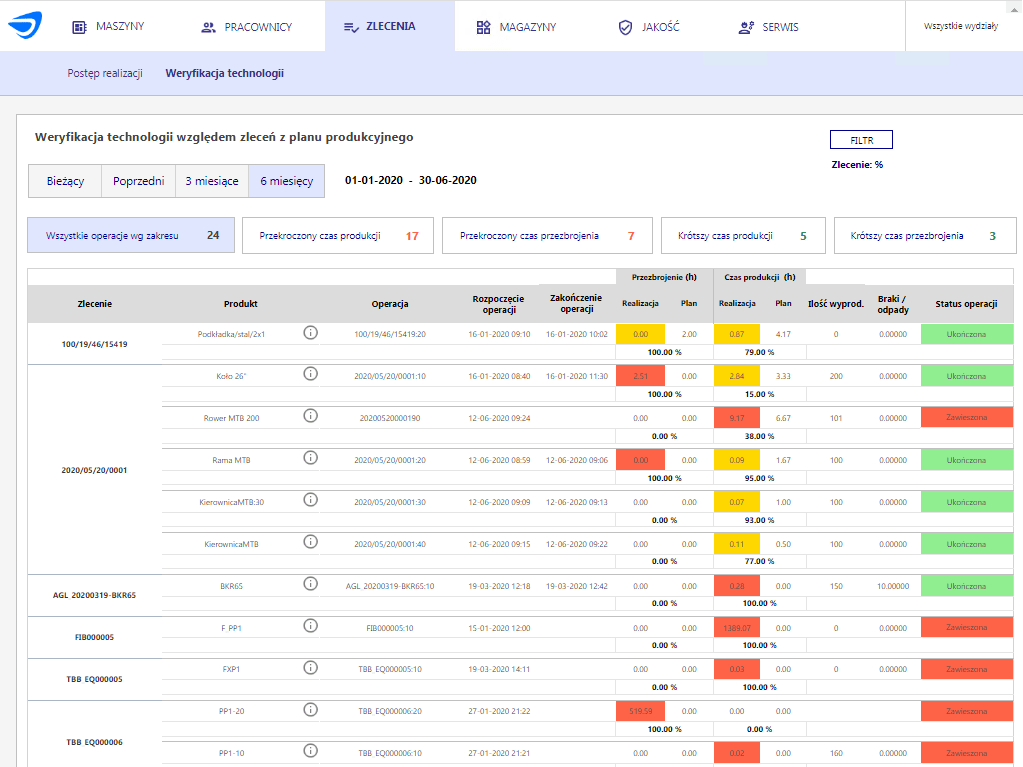

Actual data from the production process (e.g., performance time for a given operation) provides the possibility to verify it with technological data, which allows to improve the quality of production plans.

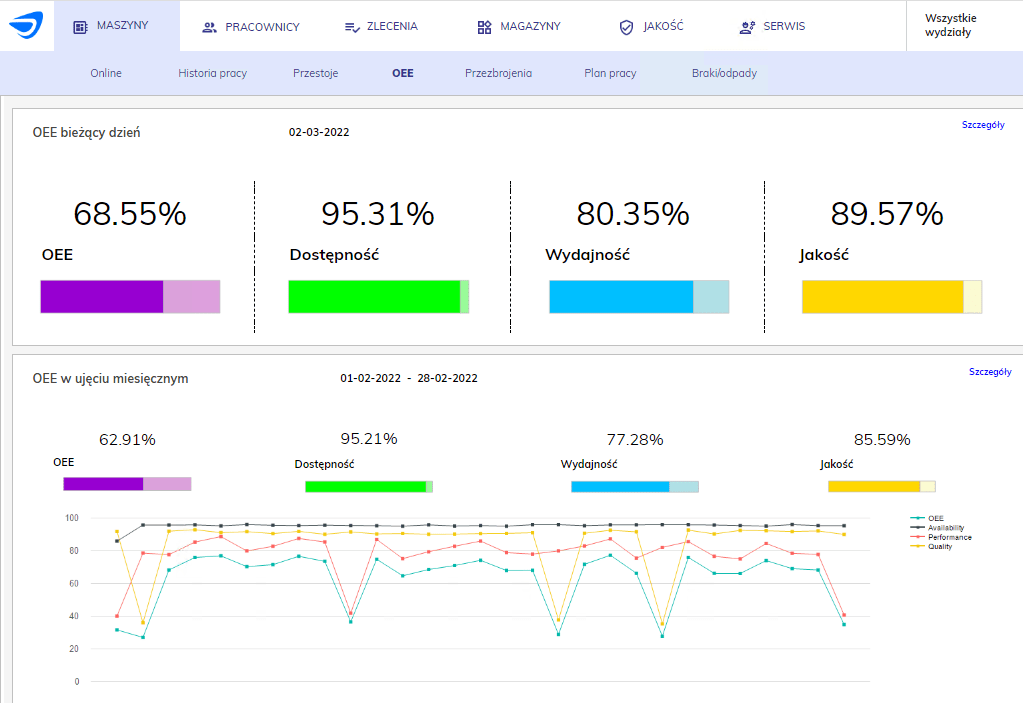

Monitor OEE based on data provided by the MES system

OEE (Overall Equipment Effectiveness), as a key parameter for monitoring the availability, performance, and quality of manufactured products, provides an overall view of the effectiveness of production equipment. It is the basis for further analysis and assessment of productivity growth potential.

XPRIMER.MES obtains the data needed to calculate individual OEE components for a specific machine or the entire department. The calculated OEE and its components are presented in a clear graphical form.

Monitor the status of your devices using IoT

By using IoT, XPRIMER.MES makes it possible to automatically retrieve information from machines, such as:

- start/stop,

- quantity produced,

- machine status,

- electricity consumed,

- occurrence of micro downtimes.

The use of machine readings within XPRIMER.MES improves the quality of collected data, acquisition time and reduces the workload for operators. This enables further effective online information transfer to other systems supporting production management (APS, WMS, CMMS, ERP).

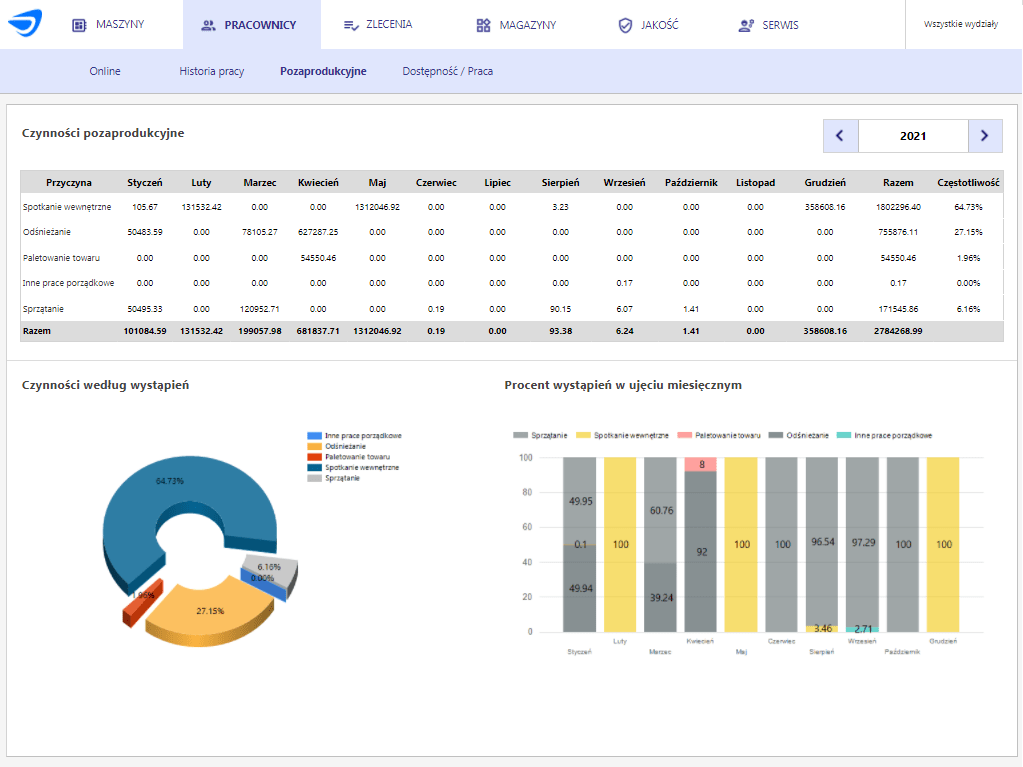

Account in detail for the working time of production staff

XPRIMER.MES allows recording all production activities performed by employees (employee entry/exit, start/end of operation, downtime, changeover). It also gives the possibility to record all non-production activities (e.g. hall cleaning).

This information can be used to account for an employee’s time, e.g., when calculating wages, bonuses, or for employee evaluations.

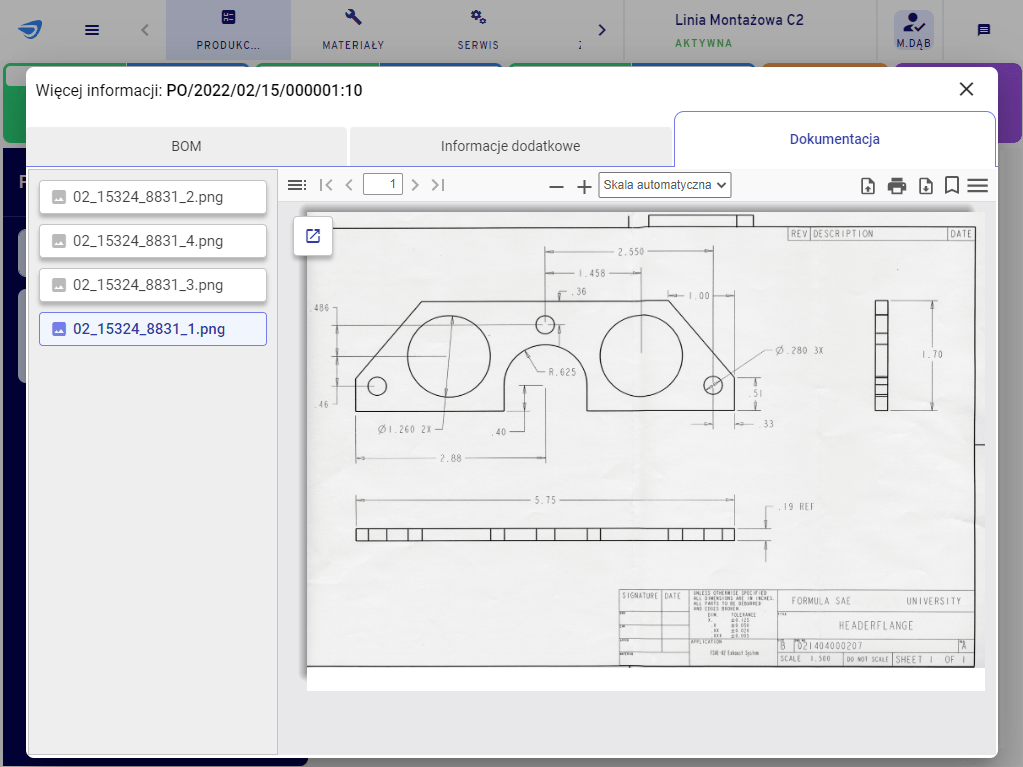

Streamline your team’s workflow by sharing documentation electronically from anywhere

XPRIMER.MES enables control of the flow of documents between individual company departments or employees. It also provides a repository of operating instructions, procedures, recipes, diagrams, and manufacturing drawings.

It enables communication with external file servers and folders located in the cloud, where drawings or technological instructions are stored.

Use data from your MES system to create personalised reports

XPRIMER.MES provides data to generate reports. The scope of reports includes information on equipment, human resources, production orders and technologies used. The way data is presented in reports is fully customisable.

Additionally, integration with other systems in the company (e.g. APS, CMMS, ERP) gives the possibility to create reports combining data from different business areas.

See how XPRIMER.MES works in practice

Contact us and arrange a meeting, during which we will present how XPRIMER.MES works.

Explore XPRIMER.MES user reviews