XPRIMER.IoT - smart manufacturing within Industry 4.0

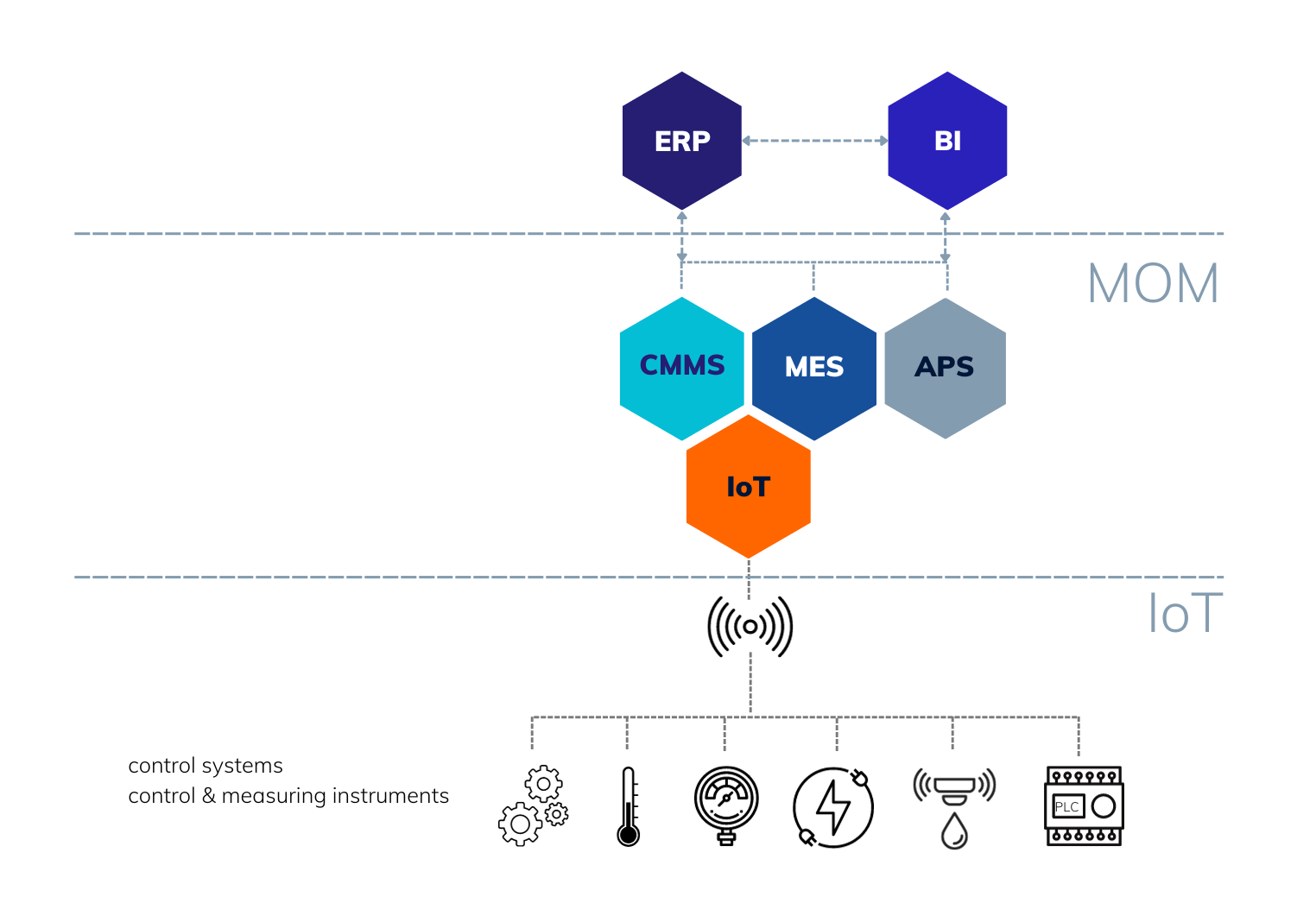

XPRIMER.IoT (Internet of Things) is a collection of tools for the exchange of information in a shop floor between sensors, devices, machines, controllers, databases and other IT systems, in particular the MES system.

Combining XPRIMER.IoT with the possibilities offered by other eq system solutions will enable you to transform your company into the Factory of the Future.

The data provided via XPRIMER.IoT enhances the degree of precision and reliability of the information available in XPRIMER.MES, which is the basis for improving production control processes and optimising the use of existing production resources.

Ensure greater precision of real-time information with XPRIMER.IoT

React quickly to incidents

using real-time data processing capabilities and intelligent notifications and alerts.

Control micro-downtimes

by reading machine signals online and automatically recording all downtimes, even those not recorded by the operator.

Calculate costs accurately

thanks to real information from production about the quantities of materials and utilities used, personnel resources involved and process flows.

Increase security

by managing data from different machines, devices, sensors, controllers, etc. on a single platform.

Optimise investment value

taking advantage of XPRIMER.IoT's scalability and ability to expand the infrastructure as needs arise.

Get real data

eliminating the influence of the human factor in the acquisition of data from production processes.

See how XPRIMER.IoT works in practice

Contact us and arrange a meeting, during which we will present how XPRIMER.IoT works.

Explore the functionalities of XPRIMER.IoT

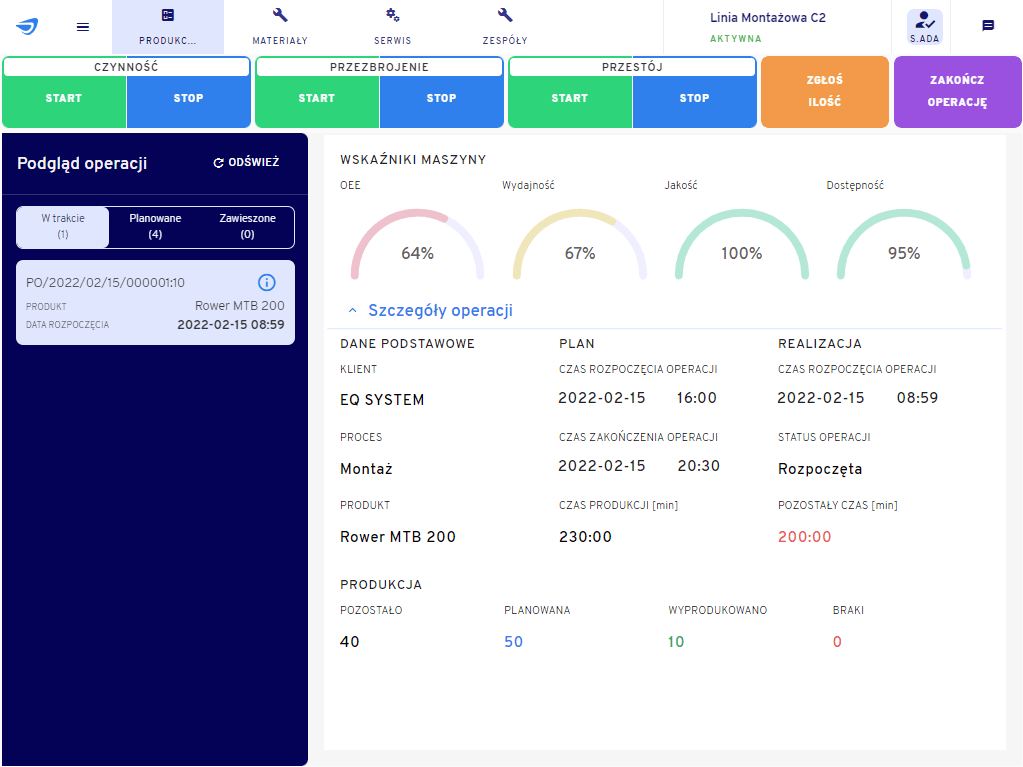

Automate data collection and provide process visibility

- quantity of correct and defective products

- machine status

- consumption of electricity and other utilities

- occurrence of micro-downtimes.

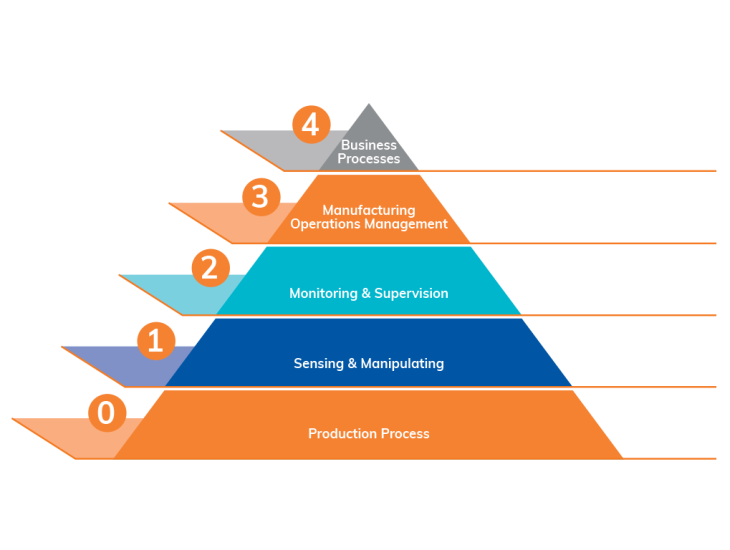

The use of machine readings with the help of XPRIMER.IoT improves the quality of the data collected, the time taken to obtain the data and relieves the burden on operators. This enables further effective online transfer of information to other production management support systems (MES, APS, WMS, CMMS, ERP) and the creation of reports from within XPRIMER.MES.

Obtain reliable, real-time machine status data

XPRIMER.IoT provides continuous access to information on the status and throughput of the machine. In addition, it is possible to record the number of correct and defective products produced and thus to precisely monitor the OEE indicator for individual machines.

Detailed data on consumed utilities (e.g. electricity) provided by XPRIMER.IoT helps to calculate the actual production costs with high precision.

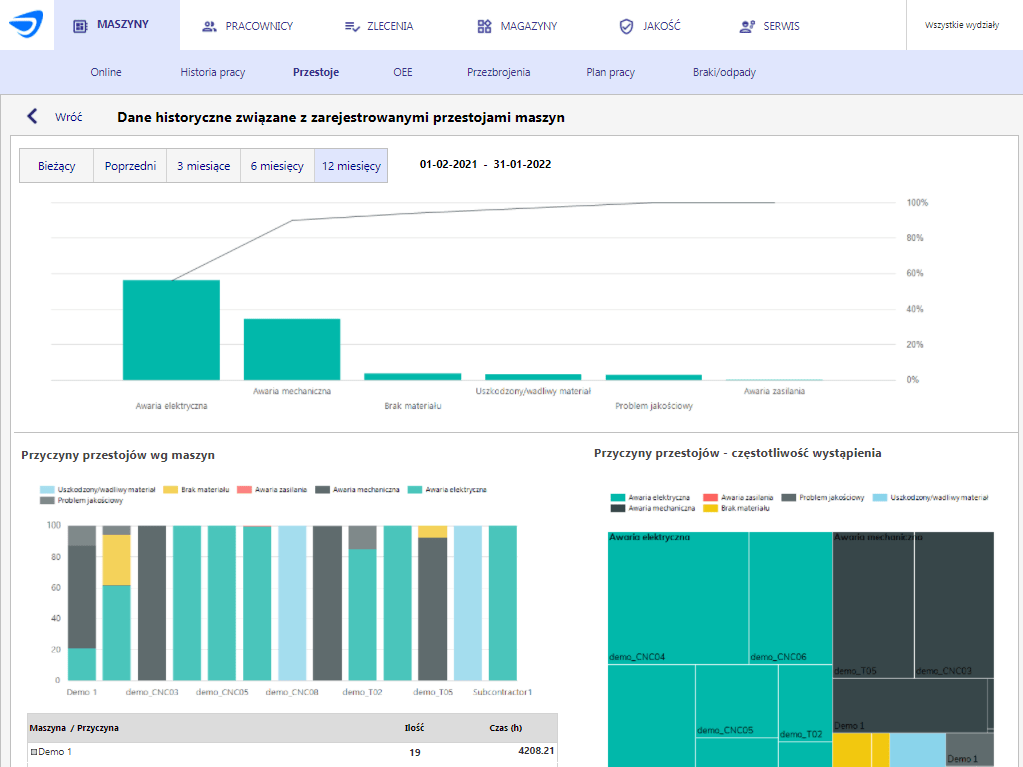

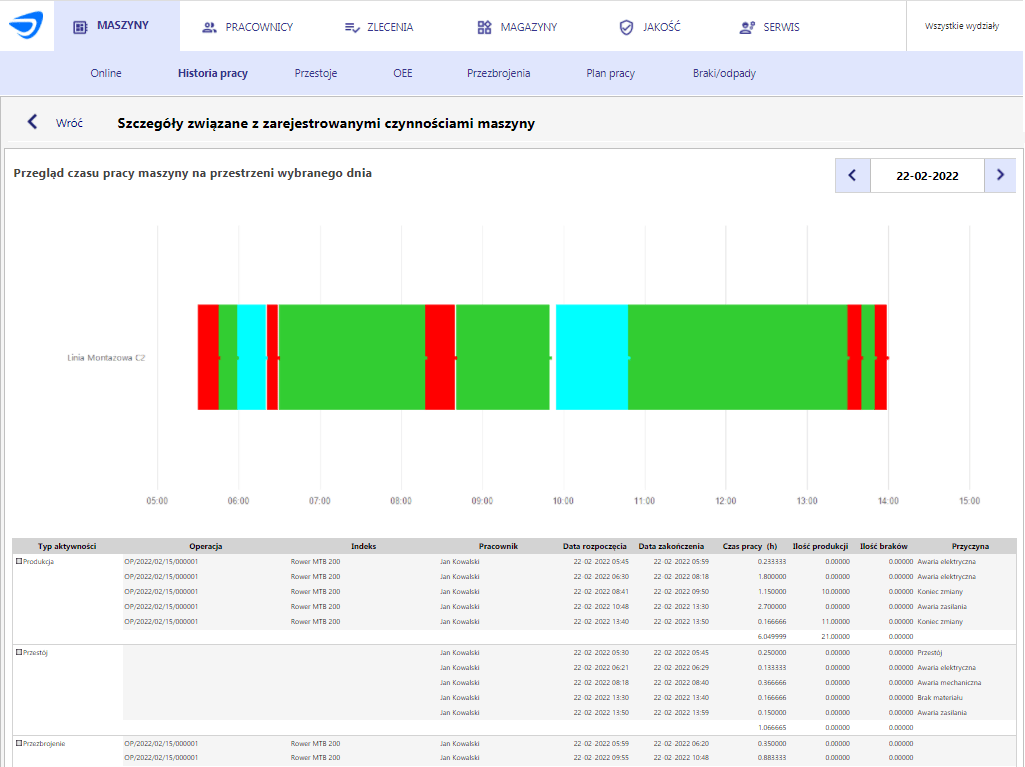

Ensure better plant productivity by monitoring micro-downtimes

A micro-interruption, which is a brief interruption of a machine or production line, measured in seconds or minutes, may seem insignificant at first sight, but the sum of micro-interruptions of all machines can significantly affect the productivity of a plant on an annual basis. Micro-interruptions are characterised by the fact that, unlike faults or failures, they cannot be reported without a proper connection to the machines.

The XPRIMER.IoT module allows the registration of micro-downtimes in real time. Their recording and analysis is an important area for optimising production processes.

Improve data security and integrity

The connection to machines is becoming more and more common in production management, but the challenge is to unify the signals acquired between different devices and ensure the secure flow of data. XPRIMER.IoT enables the unification of collected data, and managing the flow of information from one central platform ensures that it is properly protected at the same time.

Data security also means ensuring that the data is reliable and has been obtained without human intervention. This gives confidence in terms of their further processing and its use within the organisation.

See how XPRIMER.IoT works in practice

Contact us and arrange a meeting, during which we will present how XPRIMER.IoT works.

Explore XPRIMER user reviews